DURAsound

GYM FLOORING

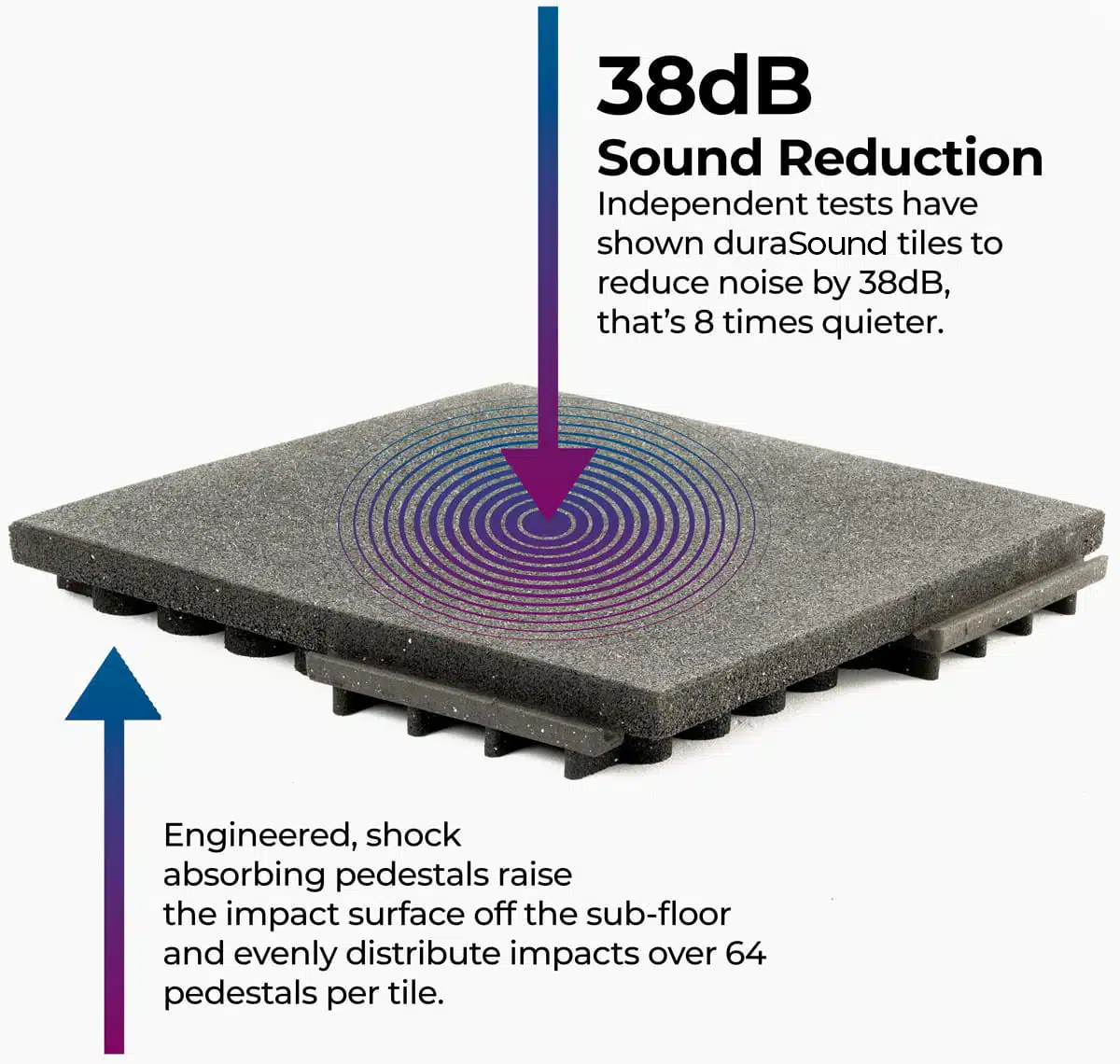

Dramatically reduce the sound transmission of heavy weight drops in any fitness facility with duraSOUND rubber acoustic fitness tiles. Performance-engineered to minimise low-frequency impact noise, control vibrations and reduce the transfer of audible structure-borne sound.

IMPROVE THE EXPERIENCE

REDUCE THE SOUND

Originally developed over 10 years ago as a sophisticated, interlocking, heavy duty flooring solution, duraSOUND tiles provide a better acoustic experience for both your customers and neighbouring businesses with sound reductions of up to 38 dB!

Available in 2 heights – 51mm and 70mm

What Makes DuraSound

Different

With mixed-use buildings now the norm, reducing noise and vibrations is a key consideration in gym design and fit-out. Large open gym spaces constructed with high ceilings and hard walls and floors can not only reflect the sound back into the space, but acoustic vibrations can also move through the structure of the building itself, into adjacent rooms or properties.

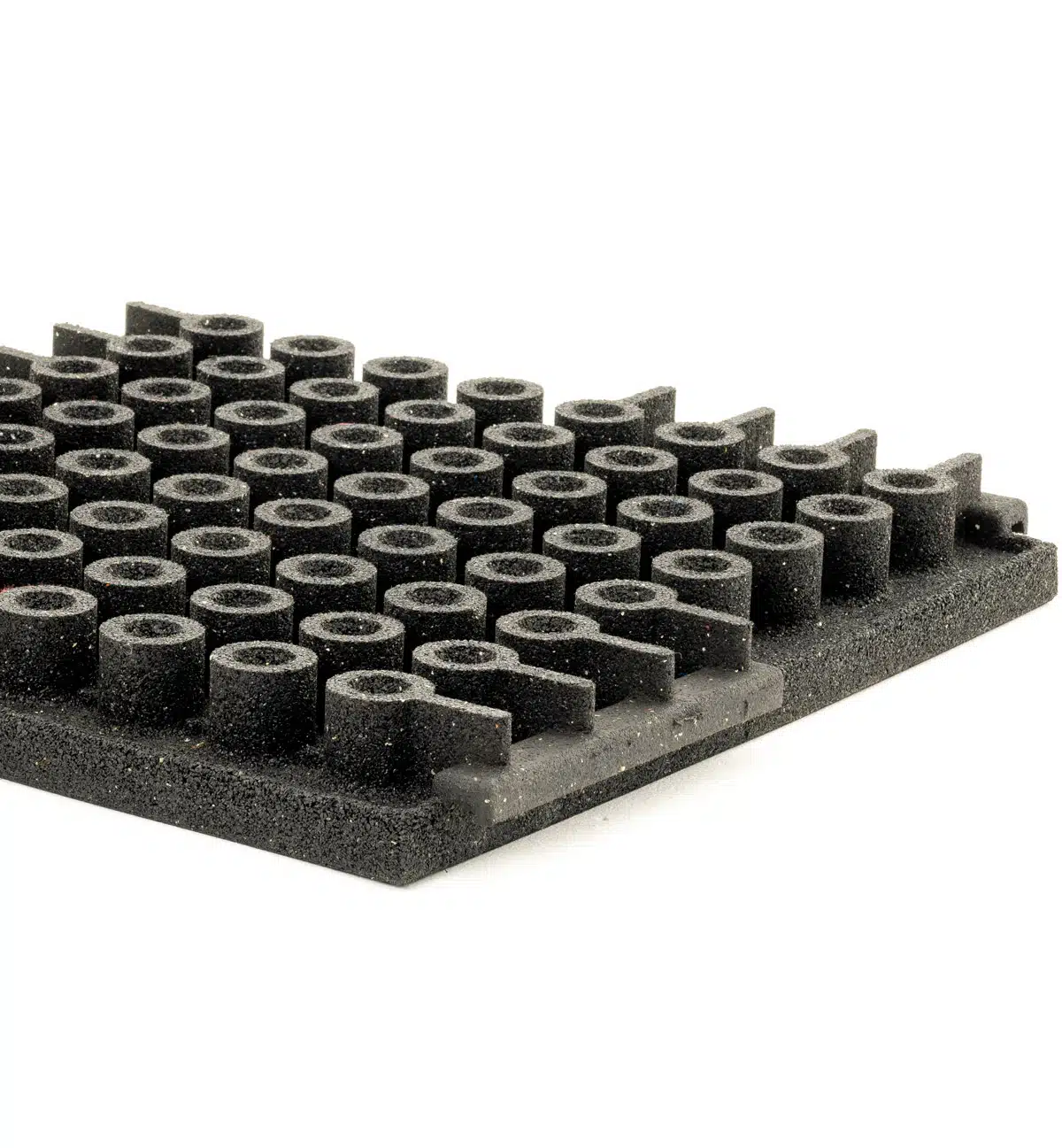

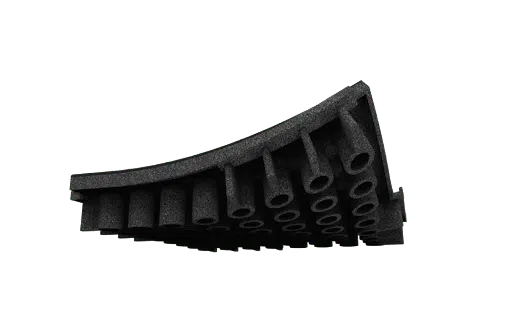

duraSOUND tiles are designed and manufactured with all the inherent properties and qualities of duraTRAIN, but with the key difference of the hollow core impact pedestals. These hollow core pedestals allow the tile to compress and absorb impact noise and vibrations, and the bigger the pedestal the more it absorbs.

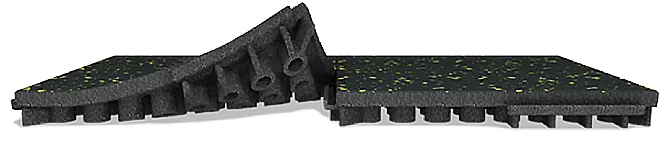

Patented, omni directional KROSLOCK mechanism locks the tiles firmly in place without the need for adhesive. This means the tiles don’t move or separate once locked in place. Additionally, DuraSOUND tiles can easily be picked up and reconfigured to fit with any changes to your gym space.

High Compression Wear Layer

Fire resistant, slip resistant, and tested for over 400,000 repeated impacts with a 360kg blunt force, duraSOUND tiles will last in even the most demanding of training environments.

Low-radius seams

duraSOUND Rubber Acoustic Tiles were designed with functionality and visual appeal in mind. When compressed and locked, low radius seams are formed along all edges for a smooth aesthetic finish.

Why duraSOUND?

Explore some of the innovative features that make duraSOUND gym flooring tiles the best and most durable on the market.

KrosLock

Patented, omni directional KROSLOCK mechanism locks the tiles firmly in place without the need for adhesive. This means the tiles don’t move or separate once locked in place. Additionally, duraSOUND tiles can easily be picked up and reconfigured to fit with any changes to your gym space.

Raised Pedestals

High Compression Wear Layer

Fire resistant, slip resistant, and tested for over 400,000 repeated impacts with a 360kg blunt force, duraSOUND tiles will last in even the most demanding of training environments.

Guaranteed to Reduce Sound and Vibrations

DuraSOUND gym tiles offer superior sound insulation and shock absorption, reducing vibration and sound travel both within your facility and in adjacent spaces. Independent tests have shown duraSOUND tiles to reduce noise by 26dB, that’s 4 times quieter.

Leigh Sports

Village

With their new gym being situated on the first floor, reducing sound and vibrations travelling to neighbouring rooms and offices was a key consideration. 51mm duraSOUND flooring was the perfect solution – specified to protect the sub-floor and reduce noise to the rest of the building – it also allowed a seamless integration with the turf track and lifting platforms.

Available in 3 Heights

51mm

70mm & 83MM

Plus Series

100% recycled rubber

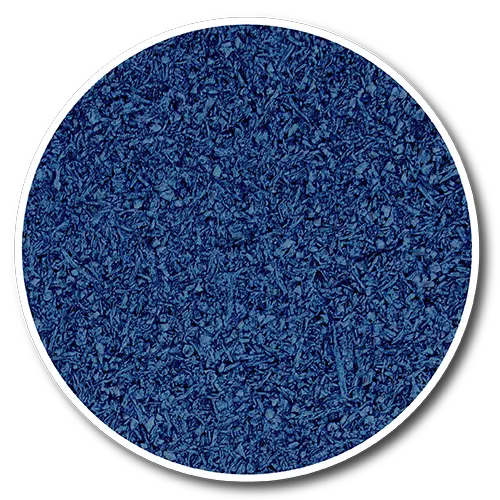

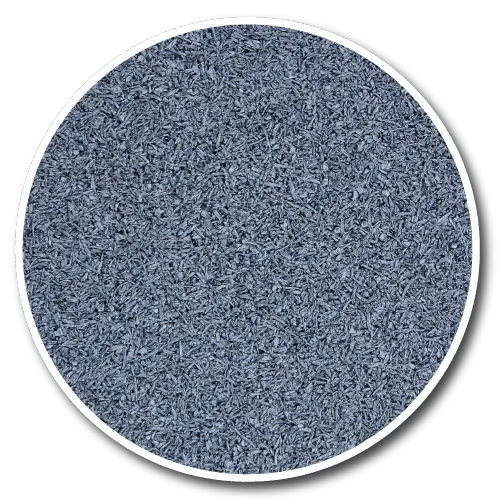

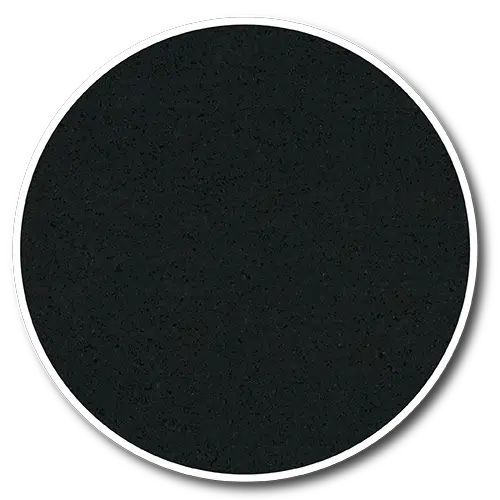

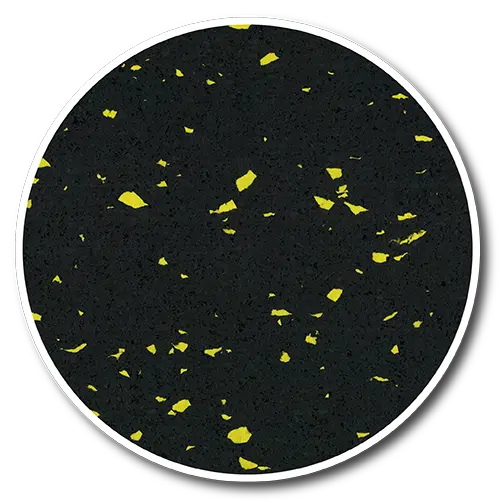

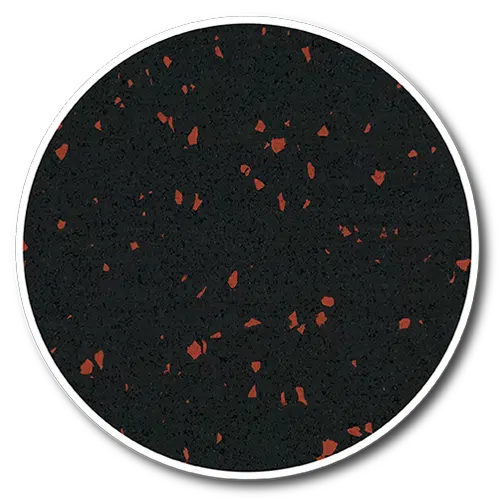

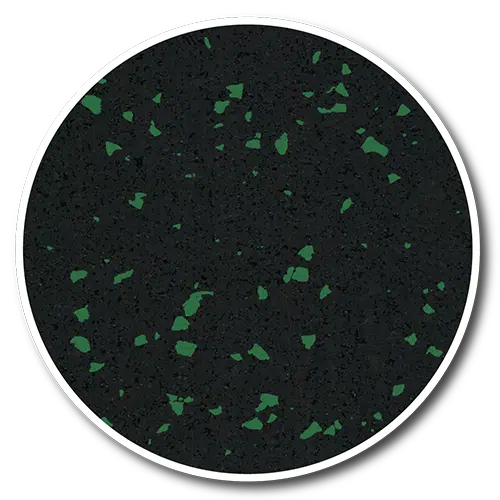

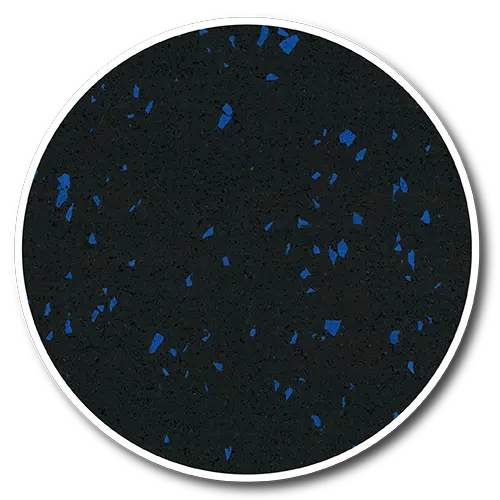

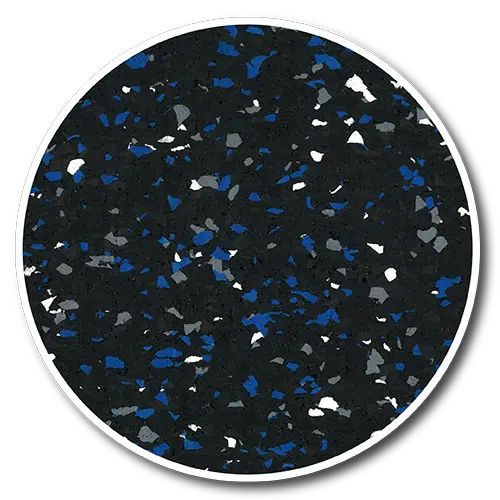

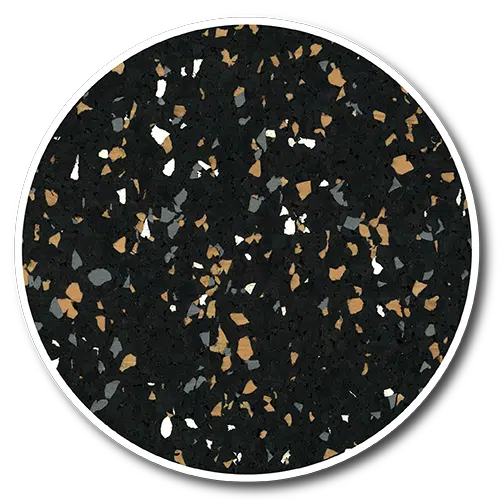

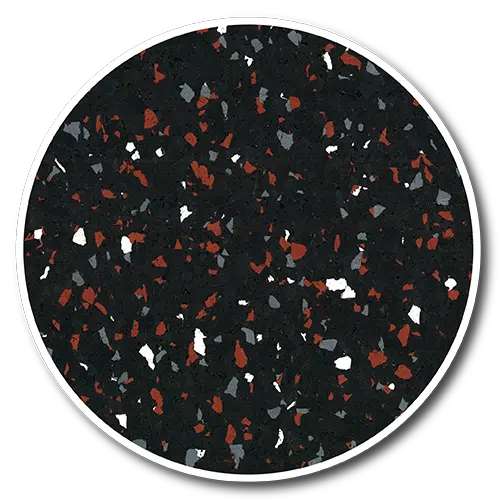

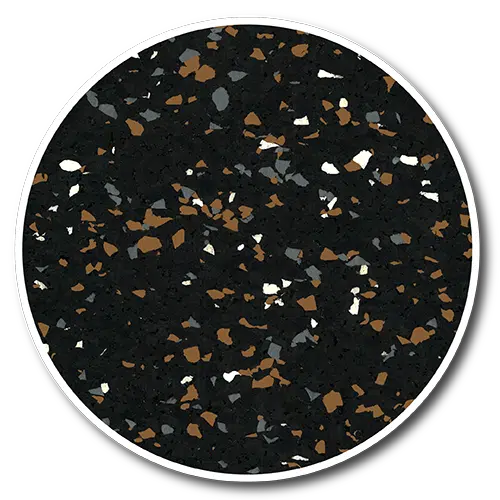

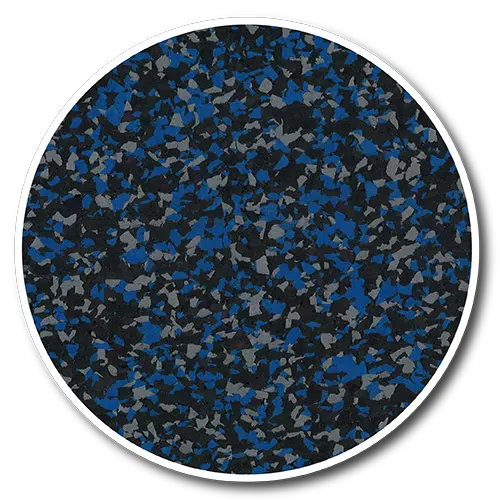

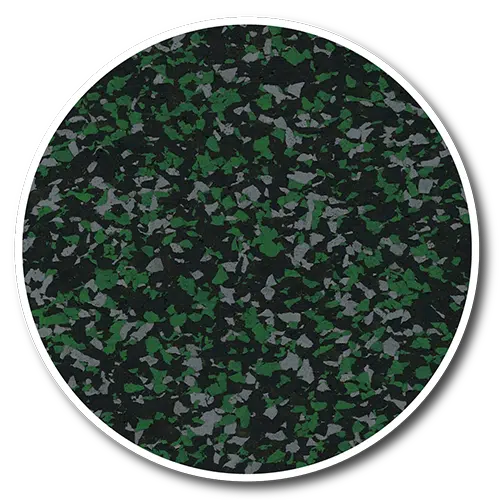

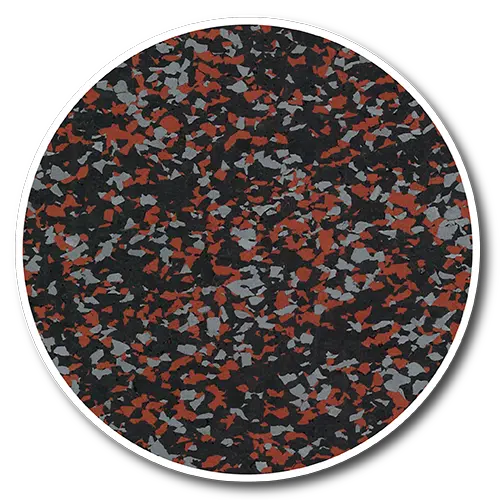

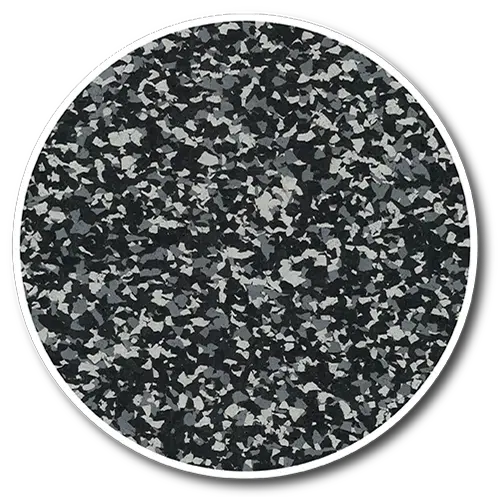

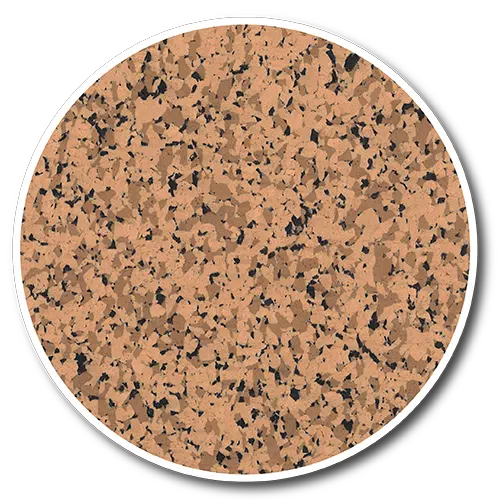

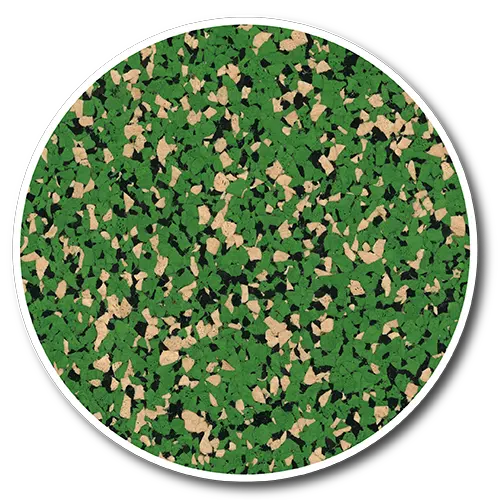

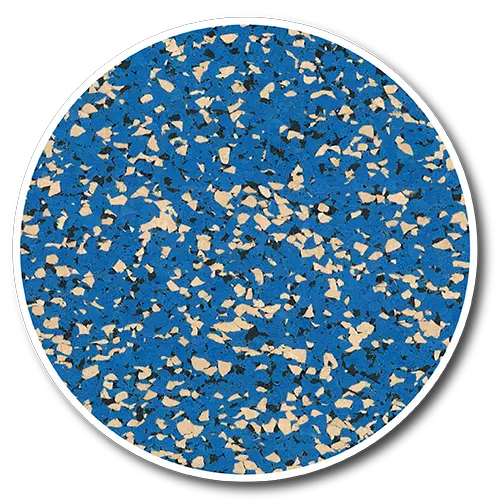

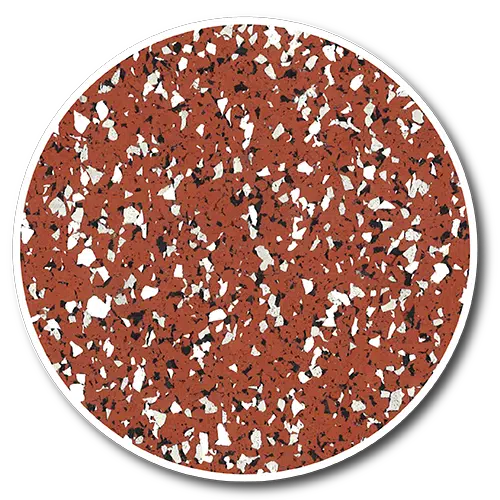

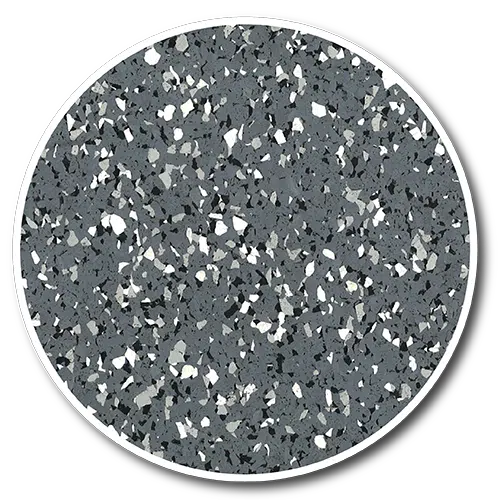

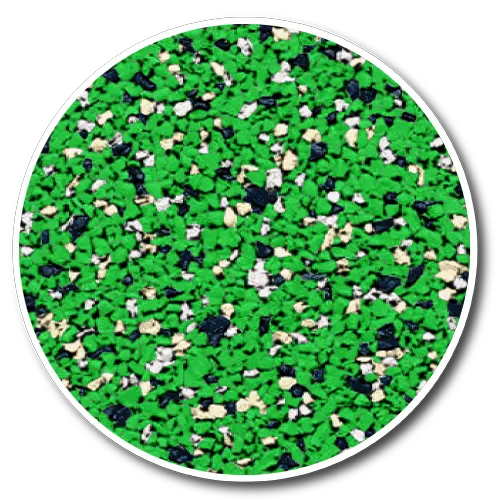

5 colours

High Compression Wear Layer

Fire classification EFL

Available in two colours

Premium Series

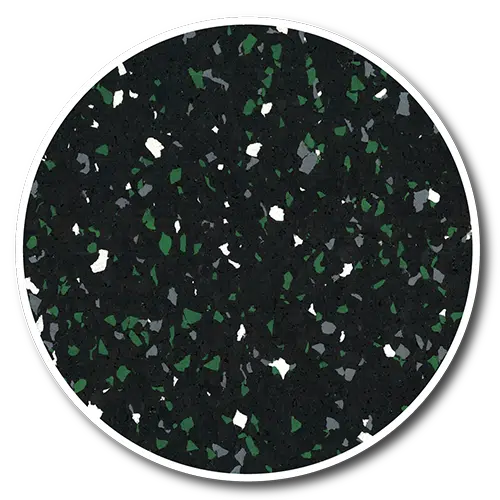

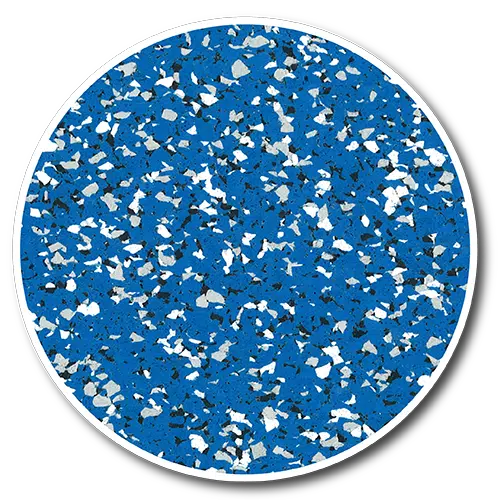

27 colours

Hygienic and easy to clean

EPDM wear layer

Add logos and training markings

Fire classification CFL

Available in twenty-seven colours

Environmentally Conscious

As an industry leader in recycled products manufacturing, DuraSOUND tiles are made in state-of-the-art facilities where continuous improvements in efficiency and responsible resource management go hand-in-hand with product quality.

100% sustainable

7%

Leed

93% recycled

750,000

0% Waste

Getting certified requires flooring products to undergo an evaluation process, which includes a review of the product’s formulation and the manufacturing site’s document control system, an onsite audit, and product emissions testing.

Performs Different Because it’s made Different

Rubber flooring is an integral part of a gym floor, and although most rubber solutions may look the same, differences in raw materials and manufacturing processes will have an impact on the performance and longevity of your gym floor and any equipment you use on it.

Precise

Manufactured using a proprietary three stage compression molding process unlike any other flooring system in the world – each tile is compressed from three different directions ensuring maximum quality.

This unique process allows the top wear layer of the system to be compression molded to a significantly higher density.

Reliable

DuraSOUND uses only the highest quality raw materials provided by the premier suppliers in the rubber and polyurethane industries. All materials are certified to meet or exceed stringent specifications and all raw materials are catalogued through retailed samples for quality control purposes.

Dependable

DuraSOUND tiles are 100% made by machine, meaning each tile can stay longer in the presses, ultimately making them stronger. Utilising the latest in process analytics and HMI (Human Machine Interface) control technology, every aspect of the manufacturing process is closely monitored and tightly controlled within the framework of ISO9001:2008.

The End Result

Simply put, duraSOUND tiles are created through the most sophisticated manufacturing process within the rubber gym tile industry. When you install duraSOUND in your training space, you are installing a gym floor that was manufactured under the strictest of controls to deliver a consistent training surface that will last. Raw materials are precisely weighed, temperatures and humidity are computer controlled, and all mixing, levelling, and molding are completed robotically so that each and every tile performs to the same exacting high standards.

When installed by our approved installation engineers, duraSOUND tiles come with a manufacturer backed 10-year warranty against defects in materials and workmanship.

FAQ’s

Do i need durasound gym flooring?

If you are thinking about having a weightlifting or free weights area in your gym you should definitely consider duraSOUND gym flooring

Do you have any testing data on the sound reduction capabilities of duraSOUND?

CAN I INSTALL DURASOUND TILES MYSELF?

We recommend that IndigoFitness’ trained installers are used because the accuracy, consistency, reliability and performance of duraSOUND can only be guaranteed if it’s installed correctly.

HOW MANY TILES ARE THERE PER M2?

As a quick guide to roughly work out how many tiles may be required, we use 2.76 tiles per square metre.

DO YOU HAVE ALL THE COLOURS IN STOCK?

We carry the duraSOUND plus tile in black as a stock item with all other colours being available in around 6 weeks.

DO YOU NEED TO USE ADHESIVE?

Can i get a free sample?

Certainly, just complete the form below and we’ll despatch it to you within 24 hours

Book A Flooring

Consultation

Virtual or in person, discuss your gym flooring requirements and ideas

with our experienced gym design consultants. Get started by filling in

some of the details below and one of our team will be back to you as

soon as possible